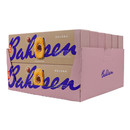

Shelf Ready Packaging: Effective Presentation with Retail Efficiency

Shelf ready packaging (SRP) or retail ready packaging (RRP) – the two terms are interchangeable – refers to products that are sent to retail stores in a format ready for immediate display. This means the products do not need to be taken out of the carton and arranged on store fixtures individually.

Shelf ready packaging can add value to the brand and the retailer, by enhancing product presentation, increasing shopper loyalty and streamlining the entire supply chain.